|

When you make an electronic circuit, the work which does the component lead of parts straight or bends the lead or cuts the lead is needed.

When handling a small part, the tool that the tip is sharp is needed.

Needle Plier Needle Plier

This is the plier with thin cutting tip.

It is very convenient to restrain, and also to hold the parts at narrow place.

It is used to make straight the component lead.

I think that a smaller one is convenient than a big one.

This tool is necessary to electronic circuit making.

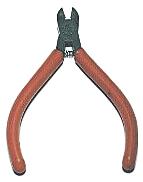

Wire Cutter (Nipper) Wire Cutter (Nipper)

This tool is used when cut the wire or cut the component lead.

The one that the top is pointed is good.

Even this, the small one is convenient.

There is a type that a ditch for the wire cut is put to the blade.

It isn't possible to use when the thickness of the wire doesn't fit.

Be careful so as not to be injured because the blade is sharp.

This tool is necessary to electronic circuit making.

Screwdriver Screwdriver

The tip of the screwdriver has various shapes. The tip of the screwdriver has various shapes.

Plus, Minus, Box, Gimlet....

Recently, the plus screw is often used. But the usage of a screwdriver is not only tightens, loosen a screw.

I might do the case force open. In that case, the minus style screwdriver is useful.

There are several kinds of sizes at the tip of driver. In the case of a plus screw, it is necessary to use the driver suitable for size especially. Otherwise, the slot of the head of a screw may be broken.

The screwdriver of the photograph right edge is a screwdriver for adjustment frequency.

It is called " Trimming screwdriver ".

Only the top is made with the metal. Other is acrylic.

Therefore the trimmer or, the coil can be adjusted without influence of the static electricity of the human body.

Tweezer Tweezer

This is a convenient tool to hold small part.

I use the top bending type.

It is your serection as you like.

Small size saw Small size saw

This is the tool that cuts the aluminum, acrylic of the case and also cut the print board.

The one that is about 6 mm of the width about 15 cm of the length of the edge is convenient when you want to cut the length of some extent like a straight line.

The thread saw is the thing of the thickness of about 0.3 mm, the width of about 1 mm, the length of about 13 cm of the edge. It is convenient when you want to cut it like a curve.

The tool of this category has a lot of kinds.

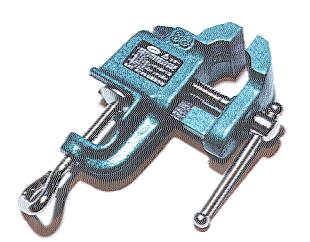

Vise Vise

This is used to fix firmly when you shave the case and also shave the print board.

It is convenient when a small vise is prepared.

The photograph thing is a small vise, the maximum width which can be fixed is about 40 mm.

Hex key wrench Hex key wrench

In the general screw, there is a ditch with plus or minus .

However, there is a screw which has a hex hole.

This wrench is the tool to strangle or to loosen such screw.

Picking-up tool Picking-up tool

This tool is to pick up the part which had rolled on the narrow place.

The four thin wires go out from the tip when pushing the red knob.

When remove the power which pushes the knob, the wire returns to the case with the spring and can grasp the part.

The crimp-style terminal press The crimp-style terminal press

This is the tool which connects the crimp-style terminal and the wire.

The tool which I am using can use the terminal of 1.25 mm, 2.0 mm, 5.5 mm.

The crimp-style terminal has the various kinds according to the thickness of the wire, the size of hole of the terminal and so on.

The tool which I am using can do the cutting of the screw, the cut of the wire cover as well as the press work of the crimp-style terminal.

|