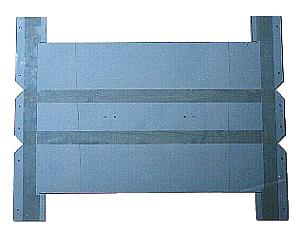

Acrylic board Acrylic board

I made the cover with the size which covers the whole equipment, bending the acrylic board with the 2-mm thickness.

I used the cutter for the acrylic resin and the small handsaw for the metal to cut the acrylic board. I am using the cutter for the acrylic resin for the part which can be cut to break by the straight line. I am using the small handsaw for the diagonal part and the part of the notch.

When bending the board, the outside curves circularly. The part in the corner gets into swing. I made the holes with the 2.5-mm size in the part in the corner to prevent the getting into swing.

I made a necessary hole before bending the board. I opened the hole which installs the clasp tool behind to adjust the installation position on the side of the chassis.

Bending the acrylic board Bending the acrylic board

I bent the part which installs the stave first. I maintained the bend part to the about 90 degrees after making the part to bend soft with the bend equipment, placing in the flat board. Then, I waited to get cold.

When it isn't possible to do the bend of the long direction at once, it bends a little from the end. Because the board breaks when putting an effort and distorting it, it bends a little. Because I put an effort too much, the part had broken.

Therefore, I installed the L angle stick of the aluminum at the part in the corner to reinforce (to conceal the breaking part).

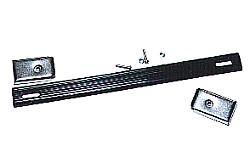

Installation of the handle Installation of the handle

Because the weight of bending apparatus-2 was light, I used the handle with the soft band type.

Installation of the clasp tool Installation of the clasp tool

I used the metal fittings with the type to stop with the wire for the clasp tool in the front.

I used the hinge of the type which it is possible to remove for the clasp tool behind.

Installation of the stave Installation of the stave

I used the 10-mm thickness wood board for the stave. The material except the wood is OK. Because the equipment can be seen, being classy, I used the timber.

I cut the stave after making the condition to have installed the cover in the bend equipment and measuring the size. In this way, the stave with the exactly good size can be made even if a few covers are warped.

|